Basic Info.

Model NO.

WLYS70

Drive Type

Electric Drive

Bucket Capacity

>1.5m³

Size

Large-Scale

Certification

ISO9001: 2000

Condition

New

Optional Bucket

Grab Bucket

Optional Bucket 2

Multi Lobe Grab

Engine Power

350kw

Weight

70t

Transport Package

Nude

Specification

Standard

Trademark

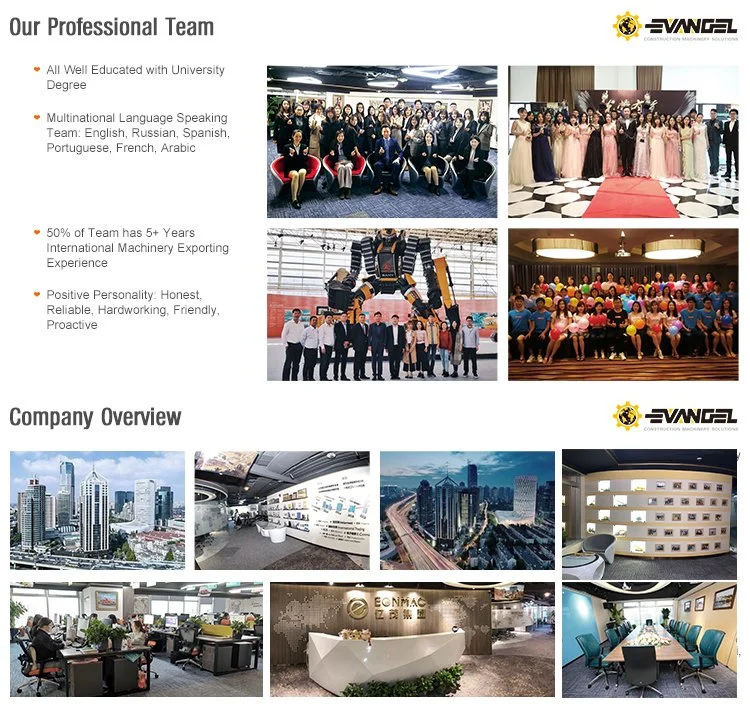

EVANGEL

Origin

Jiangsu, China

HS Code

84292090

Production Capacity

50 Units/ Month

Product Description

Chinese Top Brand New 30Ton Hydraulic Material Handler

Features:

The equipment is mainly used for railway, port and terminal loading and unloading operations, stockyard loading and unloading, stacking and destacking operations; for different loading and unloading materials, different grippers can be replaced for operation. The engine-driven operation can be used for quick transitions; the motor-driven operation in a fixed place saves energy and consumption, and saves more costs.

This product is a kind of special equipment for mobile loading, unloading, stacking and destacking, which contains many patented technologies. The product adopts a folding boom, which overcomes the shortcomings of easy turning of the grab when the soft cable of the truck crane is lifted and no downward pressure during operation, and the poor grasping effect of relatively solid materials. It is the best equipment for the loading, unloading, stacking and destacking of loose soft materials such as wood, bamboo, waste paper, soil, sand and stone.

The product has a "dual power" system for internal combustion engine and 380V electric interchange operation; electric operation can use explosion-proof motor, fully enclosed electrical, safe and fireproof, and save 60% of energy consumption than internal combustion engine operation; can quickly replace different hydraulic grabs , To achieve a multi-purpose function. Has the following characteristics:

Equipped with "dual power" interworking and interlocking (patented technology) device for internal combustion engine and 380V electric power alternating drive operation;

Electric operation has over-current, overload, overheat and leakage protection devices;

Equipped with Y/△ step-down starting device;

Automatic identification of phase sequence to prevent oil pump reversal device;

Hydraulic system self-locking, self-stop protection device when power off, oil cut off;

There are multiple compound actions during operation to improve operation efficiency;

Air-cooled radiator is installed in the hydraulic system;

The gripper can automatically rotate and change direction 360 degrees;

There is a dual-purpose air conditioner for heating and cooling during the electric operation in the control room;

The driver's cab is controlled lift;

Technical Parameters

Lifting performance parameters

Features:

The equipment is mainly used for railway, port and terminal loading and unloading operations, stockyard loading and unloading, stacking and destacking operations; for different loading and unloading materials, different grippers can be replaced for operation. The engine-driven operation can be used for quick transitions; the motor-driven operation in a fixed place saves energy and consumption, and saves more costs.

This product is a kind of special equipment for mobile loading, unloading, stacking and destacking, which contains many patented technologies. The product adopts a folding boom, which overcomes the shortcomings of easy turning of the grab when the soft cable of the truck crane is lifted and no downward pressure during operation, and the poor grasping effect of relatively solid materials. It is the best equipment for the loading, unloading, stacking and destacking of loose soft materials such as wood, bamboo, waste paper, soil, sand and stone.

The product has a "dual power" system for internal combustion engine and 380V electric interchange operation; electric operation can use explosion-proof motor, fully enclosed electrical, safe and fireproof, and save 60% of energy consumption than internal combustion engine operation; can quickly replace different hydraulic grabs , To achieve a multi-purpose function. Has the following characteristics:

Equipped with "dual power" interworking and interlocking (patented technology) device for internal combustion engine and 380V electric power alternating drive operation;

Electric operation has over-current, overload, overheat and leakage protection devices;

Equipped with Y/△ step-down starting device;

Automatic identification of phase sequence to prevent oil pump reversal device;

Hydraulic system self-locking, self-stop protection device when power off, oil cut off;

There are multiple compound actions during operation to improve operation efficiency;

Air-cooled radiator is installed in the hydraulic system;

The gripper can automatically rotate and change direction 360 degrees;

There is a dual-purpose air conditioner for heating and cooling during the electric operation in the control room;

The driver's cab is controlled lift;

Technical Parameters

| Power | Engine | 350kw |

| Electric motor | 250kw | |

| Fuel tank | 750L | |

| Walking system | Walking Speed | 10km/h |

| Max. tranction force | 135kN | |

| Gradeability | 10% | |

| Hydraulic system | Max. flow | 2*468 L/min |

| Max. working pressure | 30Mpa | |

| Hydraulic oil tank | 650L | |

| Pilot pressure | 3.8Mpa | |

| Main preformance parameters | Total weight | 70t |

| Max. lifting moment | 120 t.m | |

| Max. swing speed | 5.5 r/min | |

| Max. swing torque | 150 KN.M | |

| Dimensions | Length | 16500mm |

| Width | 4100mm | |

| Height | 3500mm | |

| Wheelbase | 5450mm | |

| Max. lifting height of cabin | 6140mm | |

| Tail swing radius | 4500mm | |

| Turntable Ground clearance | 1630mm | |

| Turntable width | 3300mm | |

| Platform width | 628mm |

Lifting performance parameters

| m | t |

| 4.0 | 30 |

| 6.0 | 20 |

| 8.0 | 15 |

| 10.0 | 12 |

| 12.0 | 10 |

| 14.0 | 8.5 |

| 16.0 | 7.5 |

| 18.0 | 6.0 |